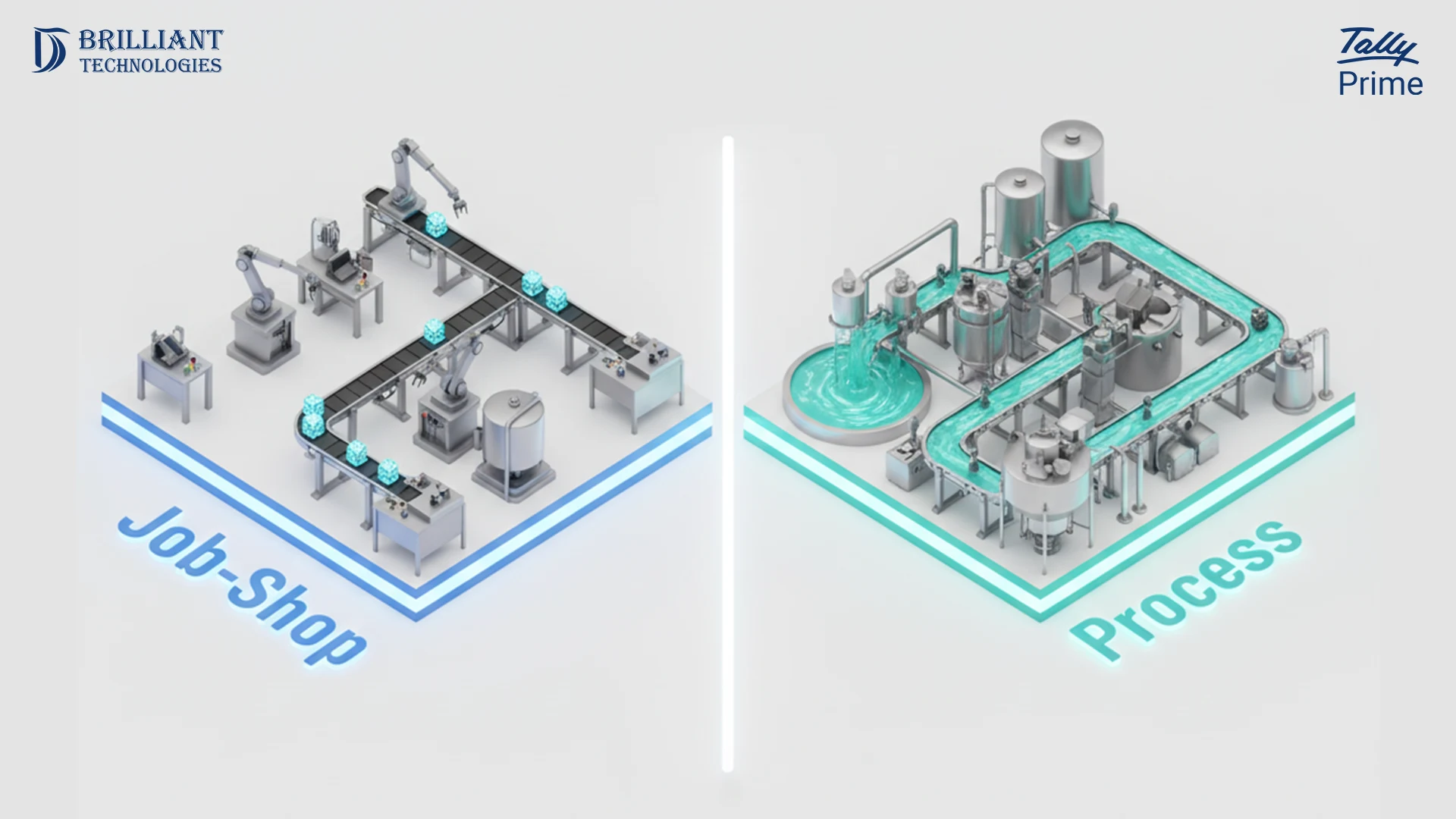

When selecting the right ERP system for your manufacturing operations, understanding the differences between job-shop and process manufacturing workflows is essential. Both workflows can improve production efficiency and streamline operations.

What is Job-Shop ERP?

In a job-shop environment, manufacturers typically produce small batches of customized products. Each order may require different specifications, so production processes must be flexible. A job-shop ERP system offers customizable workflows that adapt to varied production needs.

For example, job-shop ERP can track individual work orders and manage custom bills of materials (BOM) and routing for each job. This flexibility ensures that manufacturers can manage custom orders with varying production requirements.

What is Process Manufacturing ERP?

Process manufacturing ERP is designed for industries that produce products in large quantities using standard formulas or recipes, such as in chemicals, food, and pharmaceuticals. This workflow is best suited for continuous or batch production where consistency is key.

In process manufacturing, ERP systems help businesses manage BOMs, ensure regulatory compliance, and maintain production consistency. Process manufacturing ERP is ideal for operations where standardization is critical for high-volume production.

Key Differences Between Job-Shop and Process Manufacturing ERP

- Customization vs. Standardization

The key difference between job-shop and process manufacturing ERP is the level of customization required. Job-shop ERP systems are more flexible, managing unique orders with different requirements. In contrast, process manufacturing ERP is more focused on standardizing production processes.

- Production Flow

In job-shop manufacturing, production is dynamic and often involves different product specifications for each job. Process manufacturing ERP, however, supports more linear production processes suited for batch or continuous production.

- Inventory Management

For job-shop manufacturing, inventory management can be complex, as raw materials vary with each job. Process manufacturing ERP, on the other hand, focuses on maintaining a consistent stock of raw materials needed for continuous production.

- Tracking Complexity

Tracking in job-shop ERP requires monitoring specific orders with unique requirements. On the other hand, process manufacturing ERP tracks standard workflows to ensure production consistency across batches.

Which ERP Workflow Fits Your Floor?

The choice between job-shop ERP and process manufacturing ERP depends on your production environment. If you manufacture customized products in small batches, job-shop ERP is ideal. It allows flexibility and the ability to track unique orders and complex workflows.

However, if your production is standardized and focuses on large volumes, process manufacturing ERP will ensure better control, consistency, and compliance.

Conclusion

Choosing the right ERP system is critical for enhancing your manufacturing operations. Both job-shop and process manufacturing ERP have unique advantages, and understanding their key differences will help you select the right fit for your needs.

At BrilliantTechnologies, we specialize in helping manufacturers identify the best ERP solution. Whether you’re in job-shop manufacturing or process manufacturing, we offer expert guidance to optimize your workflow and boost productivity.

Contact us today to learn more about how the right ERP system can transform your manufacturing operations.